How often do you pass by a property that is split into apartments and think “I’d love to convert that property back into a single home – it would be amazing!” Well, that’s precisely what one customer wanted; they needed our help to combine two existing installations into one large heating system.

In most cases, we have found that large heating system projects are large extensions or upgrades to existing systems. This project is unique as the customer asked us to convert two existing independent systems into one large heating system. We adopted a different approach to our regular heating installations. Larger properties require greater heat input, that much is obvious. However, it is the delivery of heat to radiators and a hot water cylinder that required a bit of thinking. We found a solution by using a component called a low loss header.

What is a low loss header?

A low loss header is a component that allows the boiler to maintain a constant level of heat input to the rest of the system. The pump connected to the boiler, circulates water through the low loss header. Secondary systems draw heat, via their own pump, from the low loss header to the radiators or cylinder. Without one, a boiler can shut down too soon because thermostatic radiator valves shut off on heating circuits. Thus affecting balance and performance. We will write a blog on this soon to explain in full the benefits of installing a low loss header in a large heating system.

Making it work

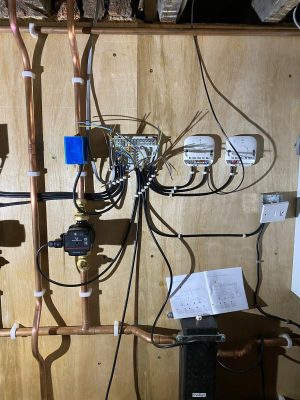

If we were to stand any chance of commissioning this large heating system, it needed a serious clean-out. So, first, we had to powerflush all parts of the existing system. We fitted a powerful Vaillant boiler in the cellar to cope with the demand for heat and hot water. As it is in the cellar, the boiler needs a condensate pump to clear the condensing water to a suitable outlet. This is also where we install the low loss header and separate circuit components. This feeds three circuits: the downstairs, the upstairs, and the hot water supply. Each circuit comes with a pump and motorised valve, providing excellent control and efficiency. In fact, we are likely to use this on some other projects in the future.

The customer wanted full control over their heating. With that in mind, we installed two nest thermostats. The first one controls downstairs heating and the hot water demands, while the second controls upstairs heating. All linked to their mobile apps.

We really enjoyed this project because it differed from our usual jobs. If you would like any information on how we could help you with your heating system, please get in touch.